SRON's new powder steel silo center multi-point material distribution device solves the problem of multi-channel feeding industry

In the field of cement, mineral powder and other powder storage and transportation, traditional steel silos are limited in diameter by the center discharge hole (usually ≤1800mm) and only support dual-channel unloading interfaces at most, which leads to three major pain points for enterprises: low multi-line feeding efficiency, high construction cost of transfer silos, and difficult dust control. How can a 10,000-ton silo accurately feed multiple production lines at the same time? Henan SRON Silo Engineering Co., Ltd. has launched a breakthrough solution based on its unique patent "a new type of powder steel silo center discharge multi-point distribution device".

SRON Solution: Core "material distribution hub" to reshape the discharging logic

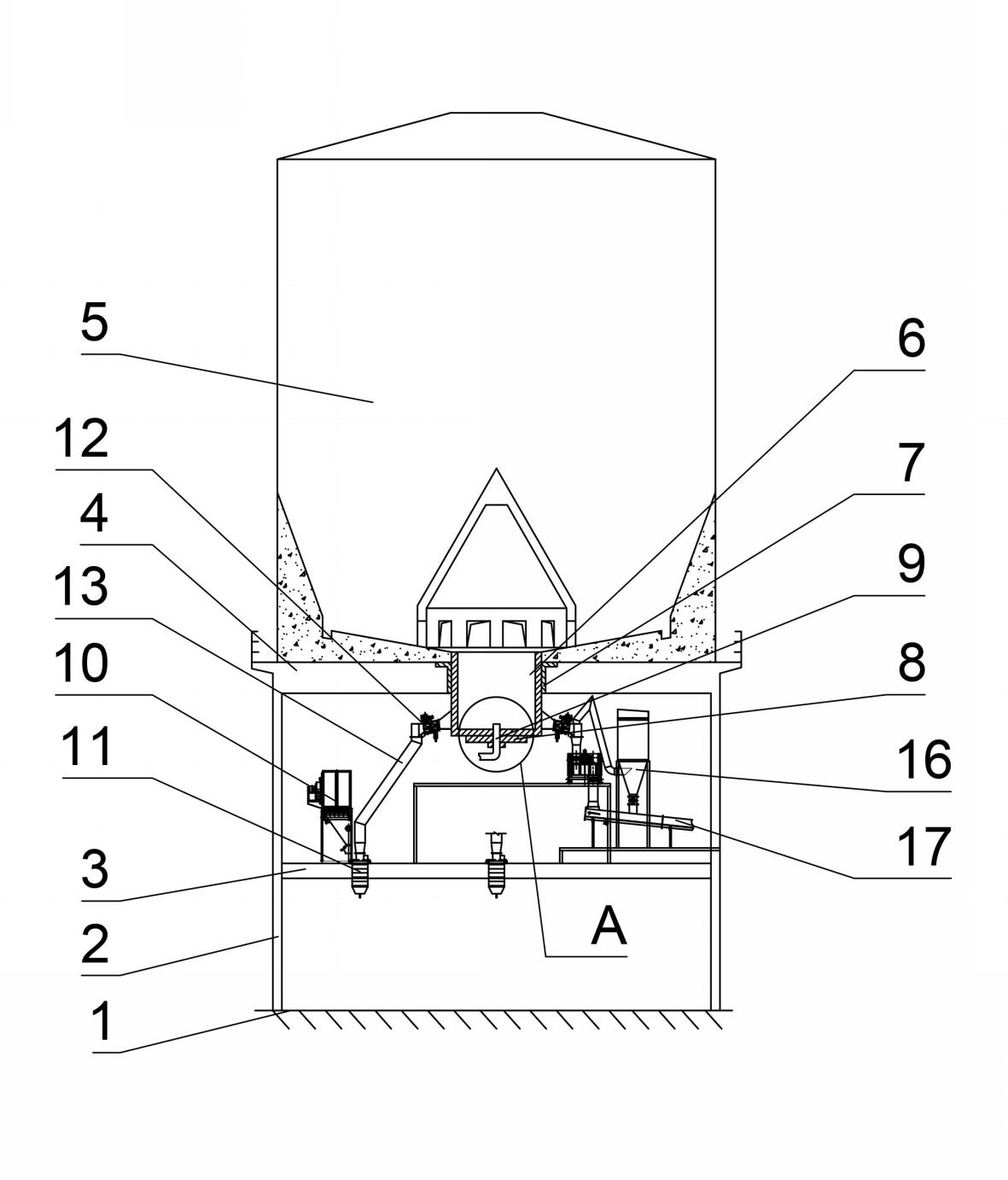

SRON engineers innovatively broke through the traditional 1800mm limit and expanded the center hole of the silo bottom to 3400mm, creating key space for the material distribution system. By setting up a 3400mm diameter annular material distribution station just below the silo bottom, an efficient material dispatching center is formed. 3-6 (expandable) efficient unloaders are scientifically arranged on the circumference of the side wall of the distribution box, breaking through the traditional 1-2-way limit. After the material flows in through the center, it is evenly distributed to each unloading point, realizing precise circumferential multi-point control, solving the industry problem of "center multi-way distribution".

Ensure smooth operation: Intelligent power activation, say goodbye to "supply interruption" and "congestion"

SRON's patent innovatively solves the core problem of multi-point material distribution: a special inflatable plate and a professional pipeline system are integrated at the bottom of the distribution box to provide stable air force for each branch; the original umbrella-shaped windshield design is combined with a circular distribution of air outlets to ensure uniform airflow diffusion; the continuous airflow keeps the powder in a "semi-suspended" fluidized state, effectively preventing compaction and arching. This system ensures that the material supply at each distribution point is sufficient, balanced and smooth, and completely solves the industry pain points such as blockage and material interruption in traditional multi-point material distribution.

Intelligent integration: modular design enables multiple production scenarios

The device is seamlessly integrated with the steel silo, adopts a three-dimensional layered design, and realizes the efficient layout of the distribution box (upper layer), discharge pipe (middle layer) and discharge port (lower layer) through the second and third layer steel structure platforms. Multi-layer sealing technology is used in key connection parts to ensure that there is no dust leakage throughout the process and meet environmental protection production requirements. The discharge port adopts a modular design, which can be quickly connected to the bulk discharge port, buffer silo or conveying equipment, and supports multiple operation modes such as direct loading, temporary storage and continuous transportation. The end of the system is integrated with a high-efficiency pulse dust removal device, which realizes gas-solid separation simultaneously during the discharge process, which not only ensures the purity of the material, but also meets strict environmental protection standards, fully reflecting the intelligent and intensive design concept of modern bulk material handling systems.

This patent of SRON not only greatly improves the reliability, flexibility and environmental protection of material unloading, and achieves a major breakthrough in the central unloading technology of steel silo, but also provides customers with more efficient, economical and environmentally friendly storage and transportation solutions, helping enterprises reduce costs, increase efficiency and achieve green development. In the future, based on the experience of project implementation in more than 40 countries and regions around the world, SRON will continue to deepen its roots in the field of intelligent storage and transportation, promote the application of technological innovation, and build a more efficient and sustainable new ecosystem for bulk material storage and transportation with partners.

Comments

Post a Comment